El diseño de las máquinas de Inyección-Soplado de Golfang están basados en los modelos de máquinas más populares a nivel mundial con sistema de aumento de presión. Como resultado, las máquinas de Golfang cuentan con una construcción sólida, durable, calta precisión, alta estabilidad, fácil manejo, bajo costo de mantenimiento y sencillo.

- Acerca de los componentes de la máquina

- Características principales de la Serie GF/IB

- Especificaciones

- Tamaño del Producto y Productividad

- Accesorios estándar y opcionales

- Video

- Unidad de Inyección: Fuerza Central con husillo en línea para unidad de plastificación.

- Unidad de Sujeción: Sistema de cilindro doble con aumentador de presión RAM facilita rápido cierre de molde, detección de baja presión y aumento de rápido de presión.

-

Molde Macho: estación doble, gira 180 grados.

- El sistema de presión hidráulica hace la operación de cierre de molde insonoro.

- El molde está diseñado para girar 180 grados sobre eje vertical. El molde puede parar en cualquiera posición lo que facilita su desensamble y mantenimiento.

- Unidad Hidráulica: El Sistema de Control de Flujo y Válvula Proporcional son utilizadas para controlar la presión y el flujo. Es sensitivo y fácil de operar.

- PLC Unidad de Controlador Programable: Se utiliza una unidad de control HMI (Human Control Interface) como unidad de control central.

- El diseño mecánico se basa en el modelo de propósito general de la máquina de moldeo por inyección. Sólo con el conocimiento fundamental acerca de la máquina de moldeo por inyección, cualquier técnico competente puede operar y mantener la máquina de Golfang.

- El precio del equipo es razonable, lo que reduce el costo de inversión del cliente en máquinas y moldes al tiempo que aumenta la producción y la competitividad en el mercado al mismo tiempo.

- La máquina horizontal hace la operación y mantenimiento más ergonómicos, y proporciona una gran interacción hombre-máquina..

- El diseño del molde adopta el método de base de molde común. Simplemente con el cambio de parte de molde, la forma, peso, o incluso la longitud del producto pueden ser manipulados. Tal característica mecánica ahorra mucho tiempo a los productores en la alineación del molde y disminuye la contratación costosa de experiencia en el cambio de molde. Se reduce el costo del molde y por lo tanto aumenta las ventajas de la competitividad en las órdenes que cumplen con las exigencias actuales de comercialización para la alta multiplicidad, sin embargo, baja monotonía en aplicaciones de fabricación..

- La máquina es la más adecuada para la fabricación de productos de alta calidad y mejores productos estándar, tales como biberones y recipientes cosméticos que incluyen productos con acabados liso, boquillas parejas, gran sellado, cuerpo y parte inferior redondos y suaves, de calidad superior, y sin marcas de fabrica..

- Una gran variedad de resinas son aplicables para una producción global, que incluye: PC, PP, PE, PS, AS, PMMA, PET, PETG, TPR, PSA, PPSU, TRITANPA y K-Resin.

|

MODEL NO.

|

UNIT |

GF/IB-100

|

GF/IB-140

|

GF/IB-170

|

||||||

|

INJECTION - INLINE SCREW

|

||||||||||

|

I06

|

I08

|

I10

|

||||||||

| Screw Dia. | mm |

40

|

42

|

45

|

45

|

50

|

55

|

60

|

65

|

70

|

| Inj. Capacity | cm3 |

135

|

150

|

170

|

250

|

300

|

365

|

600

|

700

|

800

|

| Inj. Pressure | kg/cm2 |

1715

|

1555

|

1355

|

1880

|

1520

|

1260

|

1555

|

1320

|

1140

|

| Inj. Rate | cm3/sec |

115

|

125

|

145

|

132

|

165

|

200

|

185

|

220

|

250

|

| Screw Revolving Speed | R.P.M. |

25 - 200

|

20 - 190

|

20 – 160

|

||||||

| Nozzel Sealing Force | tons |

4

|

4.3

|

4.3

|

||||||

| Heater | kw |

8.5

|

17.2

|

19.2

|

||||||

|

CLAMPING-PRESSURE BOOSTER RAM SYSTEM

|

||||||||||

| Clamping Force | tons |

100

|

140

|

170

|

||||||

| Die Open Force | tons |

10

|

10

|

10

|

||||||

| Space Between Tie Bars | H.V.(mm) |

370 x 430

|

470 x 600

|

740 x 540

|

||||||

| Platen Dimension | H-V (mm) |

570 x 640

|

710 x 840

|

1030 x 830

|

||||||

| Clamping Stroke | mm |

475

|

575

|

1000

|

||||||

|

CORE UNIT

|

||||||||||

| Number of Stations | - |

2

|

2

|

2

|

||||||

|

BLOW UNIT

|

||||||||||

| Work Pressure | kg/cm2 |

210

|

210

|

210

|

||||||

| Pump Output | l/min |

105

|

135

|

150

|

||||||

| Pump Drive Motor | HP |

30

|

40

|

50

|

||||||

| Oil Tank Cap. | l |

530

|

725

|

1000

|

||||||

| Comp. Air | kg/cm2 |

8 - 35

|

8 - 35

|

8 - 35

|

||||||

|

MACHINE DIMENSION

|

||||||||||

| Overall Dimension | Meter |

5.3x1.3x2.8

|

6.2x1.42x2.9

|

8x1.8x3.4

|

||||||

| Weight of Machine | tons |

7.3

|

11

|

18.2

|

||||||

|

POWER REQUIREMENT

|

||||||||||

| Cooling Water (UNDER 25oC) | Kcal/hr |

10,000

|

15,000

|

19,000

|

||||||

| Chilled Water (UNDER 10oC) | Kcal/hr |

7,000

|

10,000

|

15,000

|

||||||

| Air Compressor | l/min |

250

|

300

|

500

|

||||||

| Power Supply | kw |

30

|

45

|

60

|

||||||

※Golfang reserves the right to change above specification according to the product requirements.

|

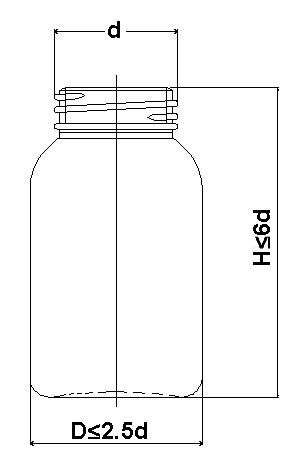

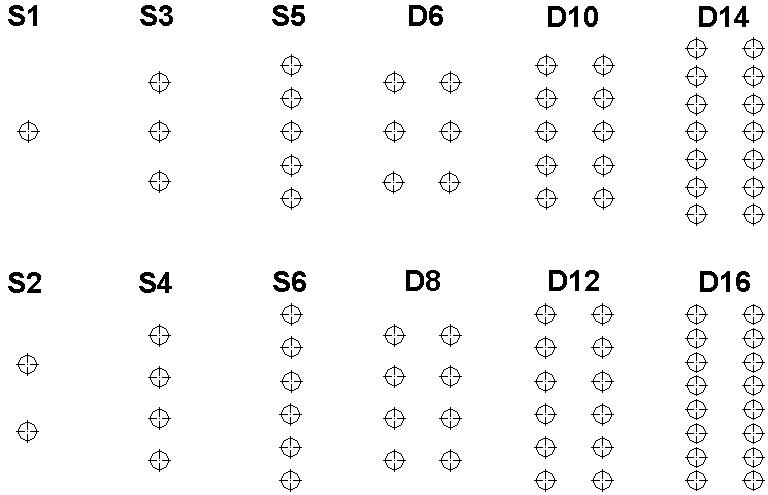

Model No.

|

d Thread out Dia. /mm

|

D (Max.) /mm

|

H (Max.) /mm

|

Max. Cap./cc.

|

W.G./Gram

|

Cycle Timer/Sec.

|

Production/hour /Bottle

|

| IB-100-S1 |

95

|

120

|

180

|

1600

|

120

|

22 – 40

|

90 – 160

|

| IB-100-S2 |

68

|

100

|

160

|

500

|

60

|

20 – 30

|

240 – 360

|

| IB-100-S3 |

55

|

95

|

160

|

360

|

40

|

16 – 28

|

380 – 670

|

| IB-100-S4 |

50

|

70

|

160

|

260

|

30

|

12 – 24

|

600 1200

|

| IB-100-S5 |

43

|

55

|

160

|

240

|

24

|

10 – 20

|

900 – 1800

|

| IB-100-S6 |

38

|

45

|

160

|

200

|

20

|

9 – 20

|

1100 – 2400

|

| IB-100-S7 |

25

|

40

|

150

|

120

|

17

|

9 – 18

|

1400 – 2800

|

| IB-100-S8 |

20

|

35

|

120

|

60

|

15

|

9 – 16

|

1800 – 3200

|

| IB-100-S10 |

17.5

|

30

|

100

|

40

|

12

|

9 – 14

|

2500 – 4000

|

| IB-100-S12 |

15

|

25

|

80

|

30

|

10

|

9 – 12

|

3600 – 4800

|

| IB-140-S1 |

125

|

200

|

200

|

3000

|

250

|

25 – 65

|

55 – 140

|

| IB-140-S2 |

100

|

180

|

175

|

1200

|

125

|

22 – 40

|

180 – 320

|

| IB-140-S3 |

80

|

150

|

175

|

700

|

80

|

20 – 30

|

360 – 540

|

| IB-140-S4 |

70

|

120

|

175

|

600

|

60

|

18 – 28

|

500 – 800

|

| IB-140-S5 |

60

|

95

|

175

|

400

|

50

|

17 – 27

|

670 – 1000

|

| IB-140-S6 |

50

|

75

|

175

|

320

|

40

|

16 – 24

|

900 – 1350

|

| IB-140-D8 |

55

|

80

|

150

|

300

|

30

|

12 – 18

|

1600 – 2400

|

| IB-140-D10 |

50

|

80

|

150

|

250

|

25

|

12 – 18

|

2000 – 3000

|

| IB-140-D12 |

40

|

75

|

150

|

200

|

20

|

12 – 18

|

2400 – 3200

|

| IB-140-D14 |

30

|

70

|

150

|

150

|

17.5

|

10 – 16

|

3100 – 5000

|

| IB-140-D16 |

25

|

50

|

150

|

80

|

15.5

|

10 – 16

|

3600 – 5700

|

| IB-140-D18 |

20

|

45

|

120

|

50

|

14

|

10 – 16

|

4000 – 6400

|

| IB-170-S1 |

150

|

300

|

300

|

12” Globe

|

420

|

50 – 90

|

40 - 72

|

| IB-170-S2 |

80

|

150

|

250

|

8” Globe

|

210

|

45 – 60

|

120 – 160

|

| IB-170-S3 |

70

|

120

|

250

|

6” Globe

|

105

|

35 – 50

|

210 - 310

|

| IB-170-S4 / LED |

70

|

120

|

120

|

4”

|

40

|

19 ~ 23

|

600 – 750

|

| IB-170-D8 / LED |

60

|

70

|

120

|

2”

|

20

|

19 – 23

|

1200 – 1500

|

| IB-170-S8 / LED |

45

|

60

|

120

|

2”

|

20

|

19 – 23

|

1200 – 1500

|

| IB-230-S1 |

160

|

400

|

450

|

16” Globe

|

800

|

50 – 120

|

30 – 102

|

| IB-230-S2 |

125

|

245

|

300

|

8” Globe

|

400

|

45 – 60

|

30 – 80

|

| IB-230-S3 |

95

|

160

|

300

|

6” Globe

|

260

|

35 – 50

|

30 – 102

|

| IB-125Y-D14 |

35

|

53

|

110

|

180

|

9

|

7.5 – 8.5

|

5900 – 6700

|

| IB-125Y-D16 |

30

|

50

|

90

|

130

|

6.5

|

6.8 – 7.5

|

7600 – 8400

|

| IB-125Y-D18 |

24

|

40

|

80

|

60

|

5

|

6 – 6.3

|

10000 – 10800

|

※Esta lista utiliza la tasa de contracción de moldeo y la gravedad específica de poliestireno (PS) como estándar.

Las especificaciones anteriores son sólo para fines de referencia y pueden variarse según el diseño del envase y tamaño total.

| ACCESORIOS | ESTANDAR △OPCIÓNN |

| Dispositivo de Parada de Emergencia |

|

| Clamping Safety Device |

|

| Eyector Neumático |

|

| Rodamiento Sin aceite |

|

| Alarma de Sobrecalentamiento de Aceite Hidráulico |

|

| Generador de Aspiración |

|

| Tolva |

|

| Circuito de Control DC |

|

| Control Electro-hidráulico proporcional |

|

| Transductor |

|

| Unidad de Control de Temperatura PLC |

|

| Variable vane pump |

|

| Compresor de Aire |

△

|

| Cargador Automático |

△

|

| Sistema I.C. de Medio de Transferencia de Calor |

△

|

| Multi-bomba |

△

|

| Tornillo especial |

△

|

| Servo motor |

△

|

| Shutoff Nozzle |

△

|

SOLICITUD

-

Botellas para bebida PS / PE / PS

-

Botellas para Yogurt HIPS

-

Envases para cosméticos PET / PS / PP / PE

-

Biberones PPSU / PA / PP / PC

-

Pantallas de lámparas PC / PMMA

-

Bombillos PC LED

-

Envases médicos PP / PE / PET

-

Botellas deportivas TRITAN / PC

-

Envases para cosméticos PET / PS / PP / PE

-

Botella otros usos PET

-

Botellas otros usos PET/PP/PE