Advanced Single Stage Blow Molding Machine

Commonly used in the production of pet bottle, the mechanical design of Golfang Single Stage Blow Molding Machine is based on the blueprint of the world's most popular machine- the plastic injection machine with pressure booster ram system. Solid construction, durability, high precision, high stability, easy operation, easy maintenance and low running cost.

- About Machine Components

- Main Features of GF/IB Series

- Specifications

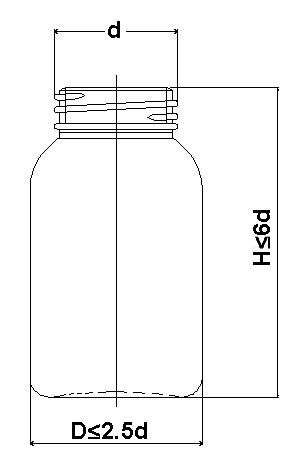

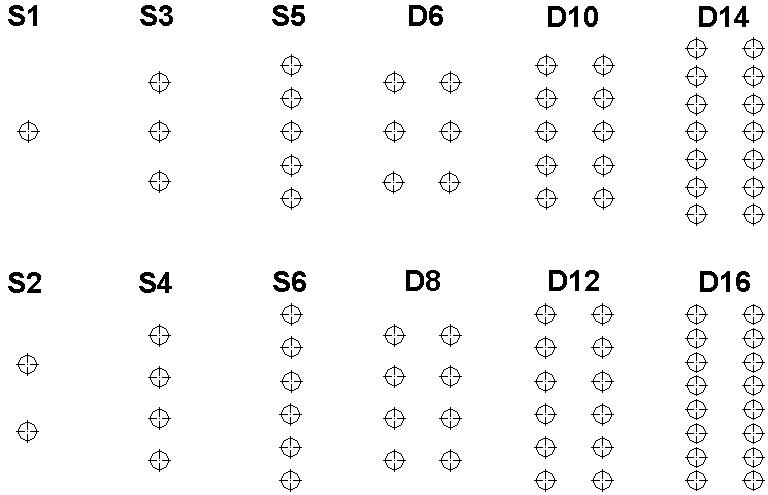

- Product Size & Productivity

- Standard and optional accessories

- Video

- Injection Unit: Central force in-line screw plasticizing injection unit

- Clamping Unit: Twin cylinder with pressure booster ram system enables fast clamping, low-pressure safety detection, and fast pressure boosting.

-

Core Mold: With two-station, 180-degree rotary unit.

- Precision hydraulic system makes the mold clamping motion noiseless.

- The core mold is designed with 180-degree horizontally rotating apparatus. The mold can stop at both operational side and rear side of it, which makes its maintenance and detachment works convenient.

- Hydraulic Unit: Proportional Electro-Hydraulic Relief & Flow Control System is used to control pressure and flow. It is easy to operate and very sensitive.

- PLC Programmable Control Unit: Human Machine Interface (HMI) is used as a central control unit in the Single Stage Blow Molding machine (IB Series).

APPLICATION

-

PS/PE Beverage Bottles

-

HIPS Yogurt Bottles

-

PET/PS/PP/PE Cosmetic Containers

-

PPSU/PA/PP/PC Feeding Bottles

-

PC/PMMA Lamp Shades

-

PC LED Globes LED

-

PP/PE/PET Medical Containers

-

TRITAN/PC Sports Bottles

-

PET/PS/PP/PE Cosmetic Containers

-

PET Others Bottle

-

PET/PP/PE Others Bottle